I needed to select a gear ratio for my servos that would serve two purposes: first, to slow the hands down to make them move more like the Weasley Clock in the movie and, second, to help in mounting all of the servos so they fit on the back of the clock face.

Gear Ratio

There are many resource online already for calculating a gear ratio. It gets a little more difficult if you want to have multiple steps, or compound gears. A good video tutorial that helped me can be found on YouTube, here.

Selecting the Gear Ratio

I arbitrarily chose a 15:1 gear ratio because it made the math between the servo and the clock face easier, that is 15° on the servo equals 1° on the clock face. The math for each increment is as follows:

Time Hand Rates

| Increment | Degrees on Clock Face | Degrees on Servo |

|---|---|---|

| 1 Second | 6° / second | 90° / second |

| 1 Minute | 1° / 10 seconds | 15° / 10 seconds |

| 1 Hour | 1° / 2 minutes | 15° / 2 minutes |

Location Hand Positions

| Location | Degrees on Clock Face | Degrees on Servo |

|---|---|---|

| Mortal Peril | 0° | 0° |

| Quidditch | 30° | 450° (1.25 Rotations) |

| Work | 60° | 900° (2.5 Rotations) |

| Theatre | 90° | 1350° (3.75 Rotations) |

| Traveling | 120° | 1800° (5 Rotations) |

| Lost | 150° | 2250° (6.25 Rotations) |

| School | 180° | 2700° (7.5 Rotations) |

| Holiday | 210° | 3150° (8.75 Rotations) |

| Church | 240° | 3600° (10 Rotations) |

| Treasure Hunting | 270° | 4050° (11.25 Rotations) |

| Home | 300° | 4500° (12.5 Rotations) |

| St. Mungo’s | 330° | 4950° (13.75 Rotations) |

This made the speed better. The Parallax 360° High Speed Servo is just that, a high speed servo. It works better at near full to full speed which is 2 rotations per second or 120 Rotations Per Minute (RPM). I experimented with reducing the speed and as it nears its dead zone, “stop”, point; it could lock up as it has not reached the desired angle yet but the speed is too slow to allow the servo to actually move any more.

At top speed, applying the gear ratio, reduces to 8 RPM or 1 rotation every 7.5 seconds.

Constraints

The other constraints I had in my gear box include:

- The smallest gear I could 3D print and fit the servo’s shaft is 12 teeth at a 30 tooth/inch pitch. (Determined through experimentation.)

- I needed the gears to not interfere with the servo mounting points.

- I needed the gear attached to the main clock shafts be large enough to allow mounting all of the servos around it.

My first attempt to do this was with Lego™ gears, but after I got my Ender 3 Pro 3D printer, I was able to create my own custom gears. It could be possible to use Lego™ gears but either the ratio or the number of gear steps would have had to change.

Outcome

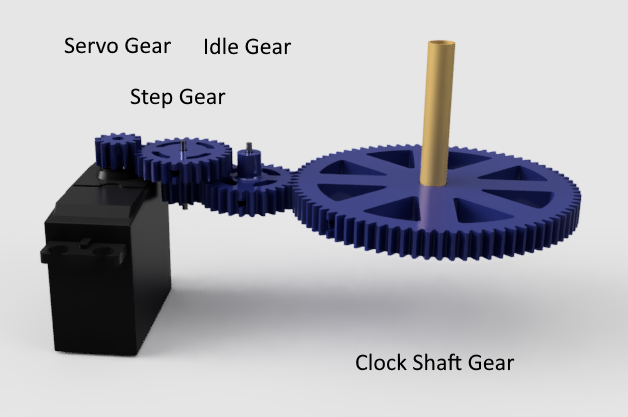

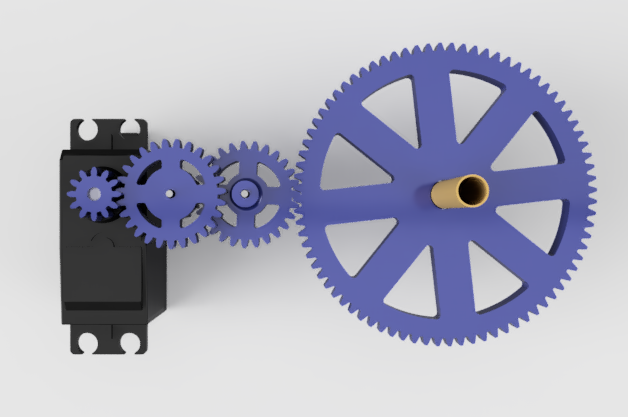

The outcome was that I needed 2 steps to make the ratio and the size of the gear on the clock shaft would depend on how far the servo is from the clock shaft. To enable that, an idle gear would also be used. The ratios came out as follows:

| First Gear | Second Gear | Ratio |

|---|---|---|

| 12 Teeth | 27 Teeth | 4:9 |

| 12 Teeth | 80 Teeth | 3:20 |

| Total Ratio | 1:15 |

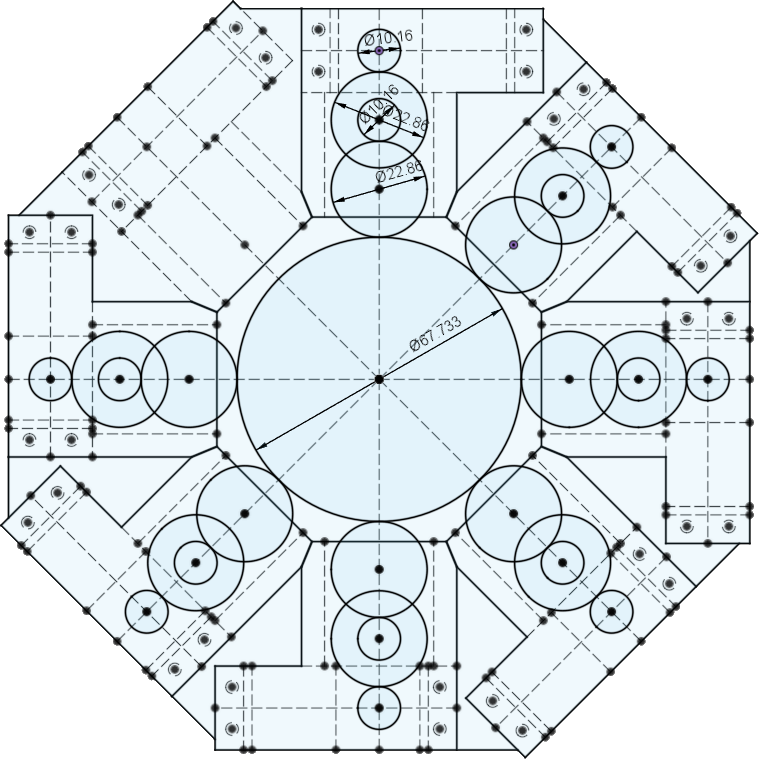

The idle gear was also made to be 27 teeth to fit in the same fixture as the step gear. As can be seen below, all seven servos fit and an eighth servo could fit as well. I modelled the gears, fixtures and checked the spacing using Fusion 360, which is free for non-commercial use.

Gear Set-Side View

Gear Set-Top View

This configuration allows for all seven servos to be mounted around the clock shaft as follows:

Gear Pattern (dimensions in mm)